LV 148 and VDA 320: Lab testing of electronic components for passenger cars with 48V on-board power supply

Overview

The LV 148 automotive test standard defines the test conditions and tests for electrical, electronic and mechatronic components and systems for use in motor vehicles with 48-volt on-board power supply. Building on and supplementing the LV 124 test standard (only for 12V on-board power supply), the LV 148 standard takes account of the increasing use of 48V power supplies in the automotive sector. LV 148 was developed and published by the VDA as recommendation VDA 320 (08/2014, “Electrical and electronic components in motor vehicles - 48V vehicle on-board power supply - requirements and tests”). The present test standard LV 148 was developed by the automotive OEMs Audi, BMW, Daimler, Porsche and Volkswagen as a common basis for the OEM standards for components in the 48 V voltage range derived specifically for each vehicle manufacturer.

Background

The need for a test standard for 48V on-board power supply systems is the result of an ongoing trend towards higher voltages in car power supplies. The successively stricter statutory CO2 limits in the EU have defined an average limit value of 95 g CO2/km for passenger cars since 2021. The use of mild hybrid vehicles in particular will make it possible to achieve this limit. These vehicles are usually equipped with a starter-generator unit that cannot be based on 12V technology, as currents of more than 200A and thus outputs of significantly more than 3kW are no longer economically feasible with 12V vehicle electrical systems. In addition to the existing 12V/24V voltage level, a third voltage level of 48V has therefore been defined, which allows a completely new electronics architecture in the car.

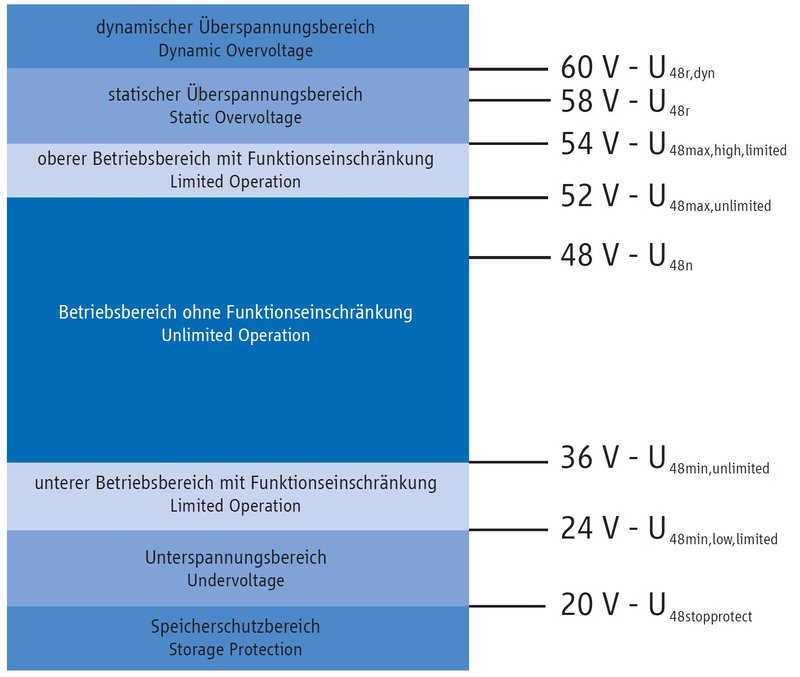

With the resulting mild-hybrid drives, not only start-stop functions have become possible, but also “recuperation”, “boosting” and “coasting”, which leads to a significant reduction in fuel consumption and emissions. This means that the strict EU limits for CO2 emissions can be achieved. In addition to the possibility of hybridization, the new 48V on-board power supply also offers the advantage of operating many other electrical consumers in the vehicle at a higher voltage. From today's perspective, 48V technology should be seen as a transitional technology for the high-voltage electrification of fully electric vehicles. The following voltages are defined in VDA Recommendation 320:

- Upper operating voltage range with functional limitation

The range between U48max,unlimited and U48max,high,limited is intended for calibrating the storage tank and the absorption of regenerative energy. - Operating voltage range without functional restriction

The range between U48min,unlimited and U48max,unlimited allows the components to be operated without functional restrictions. - Lower operating voltage range with functional restriction

Operation in the range from U48min,low,limited to U48min,unlimited is only permitted temporarily. Countermeasures must be taken to return to the operating voltage range without functional restrictions. - Undervoltage range

All voltages below U48min,low,limited are defined as undervoltage. The memory protection voltage is at U48stoprotect. - Memory protection range

The memory protection voltage is U48,protect.

Scope

The LV 148 standard based on VDA Recommendation 320 applies to electrical, electronic and mechatronic components and systems of passenger cars (<3.5t) with a on-board power supply of 48V. As part of the increase in vehicle on-board power supplies from 12V to 48V, it was necessary to supplement the existing, very comprehensive LV 124 standard. The change in voltage level primarily requires an adaptation of the electrical requirements and tests (Part 1 of LV 124), so that the tests defined in Part 2 of the LV 124 standard for 48V on-board power supplies do not need to be adapted. This applies to LV 124 tests (Part 2) such as mechanical, climatic and chemical tests as well as service life tests. I

As opposed to the previous 12-volt generator, the electric machine in the 48V on-board power supply fulfills various functions, for example it works both as a generator and as a starter and possibly also as an electric motor to support the drive. In addition to replacing the classic 12V generator with claw-pole technology, various types of integration of an energy supply designed as a starter-generator are used in 48V vehicle electrical systems. In addition to the 48-volt electric machines, however, many other electrical consumers are also integrated in a 48V vehicle electrical system architecture that were not previously supplied electrically in 12V vehicle electrical systems. All these components must therefore also be taken into account in the test requirements in accordance with LV 148, i.e. the requirements and necessary tests for all these newly used components must be defined. This applies, for example, to the following components:

- Generators and motors

- Electric power steering (EPS)

- Air and water heaters and auxiliary heaters

- Air conditioning compressors

- Pumps for different media (oil, coolant, air, fuels)

- Windshield heating

- Chassis functions, e.g. roll stabilization and electromechanical chassis systems

- Fan motors

- Connection systems

- wiring harnesses

- inverters

- DC/DC converters

- Energy and battery management

- Active electronic components

- Passive components

Tests

The electrical tests defined in the LV 148 and VDA 320 standards for 48V on-board electrical systems are extensive, but include the following tests and test areas, for example:

- Dielectric strength: Here, the components are tested for their resistance to overvoltages, undervoltages and voltage fluctuations. This is to ensure that components remain functional with varying voltages in the 48V system.

- Short-circuit resistance: This area examines whether parts and components of a 48V vehicle electrical system can withstand short circuits without damage or safety-critical failures occurring.

- Current interruptions and voltage dips: This includes the simulation of sudden current interruptions or voltage dips in order to evaluate the responsiveness and recovery of the components.

- Leakage current and insulation tests: This involves carrying out tests to check the insulation between components in the 48V vehicle electrical system.

The tests to be carried out as part of LV 148 are similar to those in the LV 124 standard, although, as mentioned, this only applies to the electrical tests part of both standards.

Compared to the LV 124 standard, however, there are a number of changes and differences in detail for tests in the LV 148 standard, which the on-board power supply of 48V entails in contrast to the voltage of 12V.

The following overview lists the tests to be carried out as part of LV 148 (48V power supply) in detail and also shows the context of the tests in LV 124 (12V power supply):

.

| LV 148 | LV 124 | |||

|---|---|---|---|---|

| Test no. | Test title | Applicability to components | Test no. | Test title |

| E48-01, a & b |

Long-term overvoltage | Components supplied via the 12-V electric system | E-01 | Long-term overvoltage |

| E48-02 | Transient overvoltage | Components supplied via the 12-V electric system | E-02 | Transient overvoltage |

| E48-03 | Transient undervoltage | Components supplied via the 12-V electric system | E-03 | Transient undervoltage |

| E48-04 | Jumpstart | Components supplied via the 12-V electric system | E-04 | Jump start |

| E48-05 | Superimposed alternating voltage | Components in vehicles with a 12-V alternator | E-05 | Load dump |

| E48-06, a&b&c | Slow decrease and increase of the supply voltage | Test case 1 for all components. Test cases 2 and 3 only for vehicles with a 12-V alternator. Test case 4 only for vehicles with a DC-DC converter. | E-06 | Ripple voltage |

| E48-07 | Slow decrease, quick increase of the supply voltage | All components | E-07 | Slow decrease and increase of the supply voltage |

| E48-08 | Reset behavior | All components | E-08 | Slow decrease, quick increase of the supply voltage |

| E48-09 | Short interruptions | All components | E-09 | Reset behavior |

| E48-10 | Start pulses | All components | E-10 | Brief interruptions |

| E48-11 | Loss of mass BN48 | Components supplied via the 12-V electric system; may not be applicable to vehicles without a 12-V starter | E-11 | Start pulses |

| E48-12 | Ground offset | Components supplied via the 12-V electric system | E-12 | Voltage curve with electric system control |

| E48-13 | Internal dielectric strength | All components | E-13 | Pin interruption |

| E48-14 | Closed-circuit current | All components | E-14 | Connector interruption |

| E48-15 | Operation in range without function limitation | Components that can be exposed to reverse polarity in the vehicle | E-15 | Reverse polarity |

| E48-16 | Operation in the upper range with function limitation | All components | E-16 | Ground potential difference |

| E48-17 | Operation in the lower range with function limitation | All components | E-17 | Short circuit in signal line and load circuits |

| E48-18 | Overvoltage range | Components with galvanically isolated portions | E-18 | Insulation resistance |

| E48-19 | Undervoltage range | Components that are continuously supplied with voltage | E-19 | Quiescent current |

| E48-20 a | Fault current, part 1, part 2 | Components with inductive parts | E-20 | Dielectric strength |

| E48-21 | Short circuit in signal circuit and load circuits | Components that are electrically connected to t.15 or to other terminals with a wake-up function for components that have an output | E-21 | Backfeeds |

| E-22 | Overcurrents | |||

| E-23 | Equalizing currents of multiple supply voltages | |||

.

Conclusion

The LV 148 standard is the main guideline of the German and European automotive industry for the specific testing requirements of electronic components in vehicles with the recently introduced 48V on-board power supply technology. Its scope of application only covers electrical tests for 48V vehicle electrical systems, such as those used in modern vehicles with hybrid or mild hybrid technology. Complementary to LV 148, however, the LV 124 standard, which was published years earlier for the conventional voltage supply in the 12V vehicle electrical system, defines all other necessary test areas, such as mechanical, climatic and chemical tests as well as service life tests.

A relatively simple way to commission suitable testing laboratories for tests in accordance with LV 148 is to submit a free request via the online platform testxchange. A short online inquiry form is used to describe which tests are to be carried out. The request is then forwarded to various laboratories at the same time. These laboratories can then respond to the request and submit offers for the required LV 148 tests.